nano tech 2021/Advanced Printing Technology Exhibition 2021/neo functional material 2021

The non-electrolytic plating method merges as manufacturing process of

FPC for 5G

December 9-11, 2020, nano tech 2021/Advanced Printing Technology Exhibition

2021/neo functional material 2021 were held in Tokyo Big Sight. Main topics

in these exhibitions are picked up.

With respect to manufacturing process for electronics device, Osaka Research Institute of Industrial Science and Technology proposed new non-electrolytic plating methods for patterning method of FPC substrate, which is possible to correspond to 5G.

Figure 1. Manufacturing process 嘆 in flexible substrate by the non-electrolytic

plating method

|

Figure 1 shows one process. First of all, a film substrate is treated by surface modification technology, such as UV irradiation or plasma irradiation. The next, anionic polymer and cationic polymer are deposited alternately, as a result, multi-layer is formed. And then, a catalyst is deposited, finally, metal film is selectively deposited on the catalyst film by the non-electrolytic plating method using commercial electroless plating solution.

Figure 2. Manufacturing process 嘇 in flexible substrate by the non-electrolytic

plating method

|

Figure 2 shows another process. Firstly, Pd series catalyst is coated on the substrate. The next, the catalyst film is exposed by UV exposure method. And then, non-exposed area is eliminated by wet-treatment. Finally, a metal film for example Cu is selectively grown on the catalyst film.

In the both processes, it's possible to gain high flatness, same as Ra 亖 nm order. This means that they can be adopted for 5G FPC substrate because of correspondence to high-frequency wave. On the other hand, the conventional method such as polyimide film + etching Cu film pattern seems to be not adopted for 5G FPC substrate because of low flatness.

Excellent organic semiconductor with high carrier mobility appears

Figure 3 Molecule structure of organic

semiconductor material "5H-21DNTT"

|

As concerns material for electronics device, Yamagata University introduced

a new organic semiconductor material "5H-21DNTT" with high carrier

mobility. It's developed by Ushio Chemix. In the experience of the university,

it is dropped on the substrate, and then, is coated on organic-TFT by the

blade coating method, which is a coating method by horizontal sweeping

of blade. Its film is not single crystal, but generally poly crystal. However,

high carrier mobility same as 15.5 cm2/Vs and high reproducibility same as 100 % were obtained respectively.

Single layer graphene is proposed as transparent conductive film for flexible device

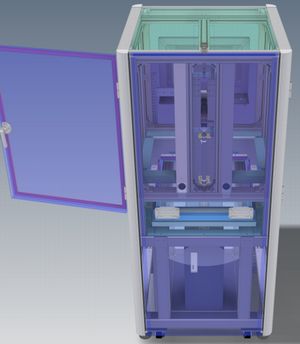

Picture 1. Transparent film with single layer graphene |

As regards graphene, which is a typical Nano technology material, Teijin exhibited a transparent film with single layer graphene. It's a transparent conductive film with single layer graphene. Its diameter is 0.34 nm only. It is considered to be connected at honeycomb. Its film can be patterned by the dry-etching method, the laser direct patterning method, and etc. Its transmittance and sheet resistance are 97.6 % and 165 兌/仩 respectively. And also, sheet resistance can be changed by forming of multi-layer (Of course, transmittance is reduced depending on reduce of sheet resistance). High quality can be obtained by high temperature process, because graphene is deposited on Cu foil by the thermal CVD method, and then, it's transferred to a plastic film.

In the booth, as figure 1, this film was exhibited at vending state. The company assumes an alternate of ITO film for flexible device. By the way, maximum size is 500 亊 600 噊 at the present moment.

Antibacterial and antiviral effects are obtained by printing of fine concavo-convex structure

Picture 2. Application example of antibacterial and antiviral structure

film |

By contrast, Ricoh proposed an antibacterial and antiviral structure film by original printing technology. In this technology, finely concavo-convex structure is formed on surface of various substrates by an original printing method, which is modification of the Ink-Jet printing method. Mold and virus are eliminated by work of its structure. In short, they are destroyed by collision with bump of its structure. Dimension of fine structure can be programmed from a few 兪m to a few dozen 兪m depending on eliminated object size. Of course, it can be directly printed on various substrates, such as glass, plastic film, paper, fiber, and so on. In actual estimate by third-party organization, dead ratio of staph aureus and influenza virus were greatly high, same as 99.9 % and over.

In the booth, mask, ABS resin, and smartphone were exhibited as application

samples. The company wants to operationalize in 2023 by some form inclusive

of license of technology. |