STELLA NEWS SITE is managed by Stella Corporation Inc. |

Innovation Japan 2025 (August 21 - 22) |

||||||||||||||

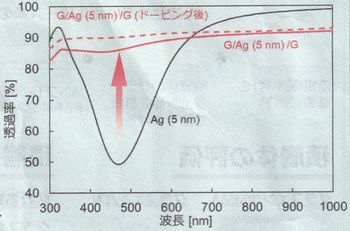

August 21 - 22, Innovation Japan 2025 was held in Tokyo Big Site. New topics of electric device are closed up. Support low resistance and high transmittance by grafen/Ag/grafen stack layer

In this experiment, a glass was used as a substrate, but plastic film will be used in near future. By the way, it can be patterned by photolithography + O2 dry etching or direct O2 dry etching using mechanical metal mask.

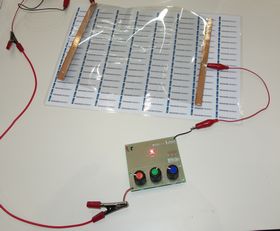

Kogakuin University proposed a carbon Nano tube (CNT) with silicon complex ink as a newly transparent conductive film. This ink is coated by various coating methods, and then, treated by a specific acid. Of course, it can be directly coated on various plastic films. Its sheet resistance is approximate 500Ω/□, and optical transmittance is 90% and over. Its flexibility is superior. Picture 2 shows LED system with this conductive film. If this sample is bend, LED keeps emitting state, and furthermore, emitting state is not changed, too. Flexible organic film solar cell is pilot-produced by use of new polymer ink as anode

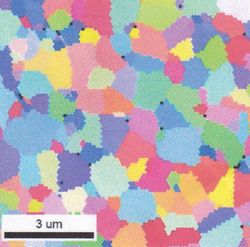

As picture 3 shows roll type organic film solar cell (30×100cm) using this transparent anode. It's composed of all polymer material including p-type and n-type organic semiconductor. Power conversion efficiency (PCE) is relatively high same as 7% in spite of all solution polymer type device. Amorphous ITO film is polycrystallized by excimer laser anneal Kyushu University proposed that amorphous ITO film was polycrystallized by excimer laser anneal. Damage against substrate is minimized by local annealing to surface neighborhood of ITO film, which has high absorption of UV light.

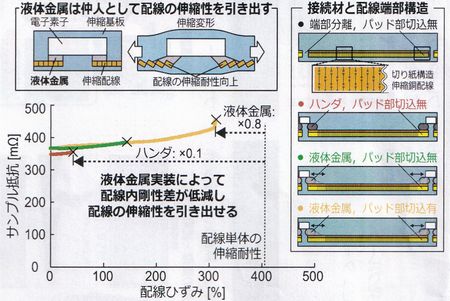

Stretchability of device itself is enhanced by use of liquid metal as mounting connection As concerns other field, National Institute of Advanced Industrial Science and Technology (AIST) reported a mounting technology of electric device by use of liquid metal. As you know, liquid metal such as Ga+In or Ga+Sn functions as liquid in wiring because of low melting point (<30℃), and has high stretchability same as 500% and over. In this time, the research group proposed to use this liquid metal as connection of device and wiring. In the first experiment using non stretchable wiring, stretchable resistance was increased at just stretch amount of liquid metal. And also, it's increased to 300% in connection area.

|

||||||||||||||

| REMARK STELLA NEWS SITE is a free news site of FPD and PCB by Stella Corporation Inc.(This company does not release these FPD and PCB related products.) |

Novel system was released as manufacturing system of emulsion film mask. |