STELLA NEWS SITE is managed by Stella Corporation Inc. |

FINETECH JAPAN 2024/15th FILMTECH JAPAN/13th PLASTIC JAPAN/11th Metal Japan/4th Sustainable Material Japan (October 29-31) |

|||||||||||

October 29 - 31, FINETECH JAPAN 2024/15th FILMTECH JAPAN/13th PLASTIC JAPAN/11th

Metal Japan/4th Sustainable Material Japan were held in Makuhari Messe.

Main topics about material in these exhibitions are picked up.

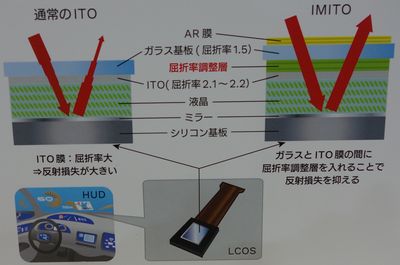

Picture 1 shows instrument panel using SVR. Left is a sample using SVR only, right is a sample using SVR and AR film. In the left, light reflection was not almost observed. Light outcoupling efficiency of Micro-LED is improved by combination of high and low refractive index materials On the other hand, TAIYO HOLDINGS proposed to use high refractive index maternal and low refractive index material for microlens array (MLA), in order to enhance light outcoupling efficiency of Micro-LED. The former's refractive index is 1.7. It's patterned on RGB sub-pixels at half-sphere shape by coating, exposure, develop, and baking processes. The latter's refractive index is 1.49. It's coated patterning-free. The both can be easily coated or laminated by existing methods. By the way, enhanced effect of light outcoupling efficiency is not sure at the present moment. Reflection loss is minimized by use of index matched ITO

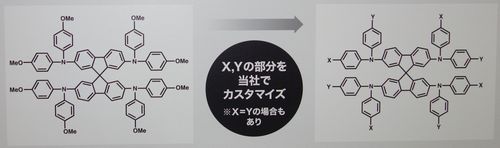

As figure 1, it's effective for LCOS(Liquid Crystal on Silicon) in the booth, particularly, best suitable for head-up display. JFE proposed original hole transport material for organic series solar cell As regards organic series solar cell, JFE group (JFE Steel and JFE Chemical) proposed metallic oxide film was deposited as electron transport material by electrolytic plating method following last year, and also, original hole transport material for perovskite solar cell in this time.

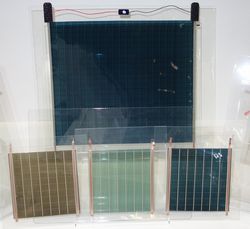

In the booth, small perovskite solar cell and practical organic film solar cell using electron transport material and hole transport material were exhibited. In the former, substrate with this film will be supplied or manufacturing technology will be licensed, on the other hand, in the latter, material itself will be supplied to device makers.

By contrast, Reiko exhibited solidly encapsulated organic film solar cell by high transparent low resistance film and high-barrier film. In the former, conventional ITO film is deposited on PET film with coating layer. Its sheet resistance and light transmittance are 14.9 Ω/□ and 87.2 % respectively. Furthermore, workability of laser cutting is excellent. The company will supply stack film of high-barrier film/sealing material/high transparent low resistance film. Flexible device can be relatively manufactured because of above layer structure in spite of use of conventional ITO film. By the way, water vapor permeability (WVTR) is approximate 5×10-4g/m2/day. New functions are generated by fine concavity and convexity structure on substrate

|

|||||||||||

| REMARK STELLA NEWS SITE is a free news site of FPD and PCB by Stella Corporation Inc.(This company does not release these FPD and PCB related products.) |

| Situation of benchmark test We are testing various treatments in respective lacations by using customer's sample substrate always. Situation of benchmark test is this page. |