STELLA NEWS SITE is managed by Stella Corporation Inc. |

Material New Technology Presentation Meetings (October 30) |

|||||||||||||||||||

October 30, 2018, ĀgMaterial New Technology Presentation MeetingsĀh was held

in JST. In this here, an oral presentation by Dr. Furuta of Kochi University

of Technology is picked up.

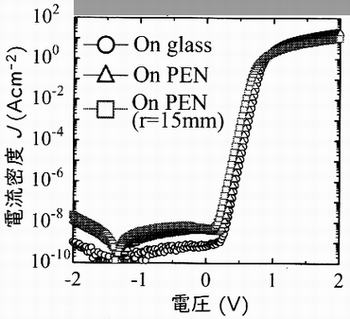

IGZO film was deposited by the conventional sputtering method. However, a certain gas was purged into the process chamber with O2 gas (flow rate 1 %) due to low annealing process. This is reason why oxygen defect which is a typical defect in oxide semiconductor is suppressed. In fact, if this gas was doped at 8 % ratio , carrier density was reduced from 1.8Ā~1018cm-3 to 7.2Ā~1016cm-3. As a result, annealing temperature can be lowered to 150 Āé. Figure 1 shows transfer characteristics of sample device, was manufactured by this low temperature process (150 Āé). It was almost same as that of the conventional device with glass substrate. Table 1 shows comparison of device catachrestic. While they are compared, carrier mobility and hysteresis of new device were mere low, however, subthreshold characteristic was superior. In short, if 150 Āé low temperature process is adopted, high quality oxide transistor can be manufactured, and then, PEN film can be used as a substrate.

Reference 1)FurutaĀFA New Low Temperature Forming Technology in High Quality Oxide-Semiconductor Manufacturing Process for Flexible Device, Material New Technology Presentation Meetings!, pp.3-6 (2018.10) Ā¶This title is translated arbitrarily by Stella News Site because of without English edition of presentation material. |

|||||||||||||||||||

| REMARK STELLA NEWS SITE is a free news site of FPD and PCB by Stella Corporation Inc.(This company does not release these FPD and PCB related products.) |

|