STELLA NEWS SITE is managed by Stella Corporation Inc. |

CEATEC 2022 (October 18 - 21) |

|||||||||||||

October 18 - 21, CEATEC 2022 were held in Makuhari Messe. Main topics are

closed up in this here. By the way, the online exhibition is opened on

the official homepage (https://www.ceatec.com/en/) until October 31st.

However, response speed becomes to be slower because of its display mechanism, and rewriting time was about 15 sec. For this reason, E-Ink changed driving method from a-Si TFT to IGZO (InGaZnO) -TFT, which had high carrier mobility. As a result, driving voltage can be highly applied. Therefore, it's possible to rewrite monochrome image for 0.35 sec, and color image for 0.5 - 1.5 sec. Sharp will supply IGZO backplanes to E Ink from now. Kyocera exhibits an originally aerial display system On the other hand, Kyocera exhibited an aerial display system, which was originally developed.

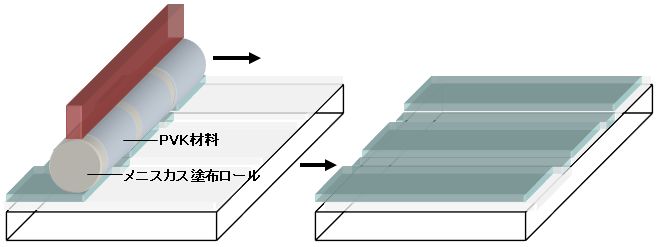

Medical system, amusement system, exhibition display, and dashboard of automobile are considered to be useful as its applications. The company will release this system oneself at 2026. Toshiba brushed up perovskite solar cell using plastic substrate With respect to perovskite solar cell, Toshiba exhibited a real flexible device with PET plastic substrate unlike in last year (online exhibition). Its IPCE (incident photon-to-current efficiency) was enhanced from 15.1% to 16.6% in this year. Furthermore, device size was enlarged to 703 cm2. However, release time will be 2025. Most feature is an originally developed coating technology (the meniscus coating method) of perovskite (PVK) layer. Figure 1 shows its process. It's possible to uniformly coat PVK ink on a large substrate by making use of surface tension of ink. In the past, the company coated PbI ink, and dried, the next, coated MAI ink, and dried. In short, crystal MAPbI3 was obtained by 2 step process. In this time, 1 step process was developed. Concretely prepared MAPbI3 in advance is coated with control of crystal growth by the meniscus method.

Sharp exhibited a flexible perovskite solar cell for the first time By contrast, Sharp exhibited a perovskite solar cell in the first time, and announced to release as a flexible solar cell in the near future.

As picture 3, 30 ü~ 30 cm module was exhibited with PET film. However, its IPCE was not disclosed because of first prototype. The company will release the device in 2024 - 2025. Micro Technology appealed ultra-thin glass with patterned electrodes

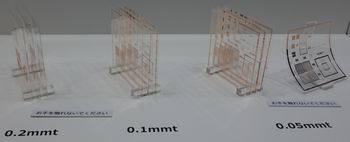

Of course, the company supplies this ultra-thin glass with some patterned electrodes. In the booth, soda lime glass samples (200ü~200ćo) with Ti/Cu seed layers and patterned Cu electrode were exhibited. As picture 4, it's possible to curve easily in case of 0.05 ćo thickness. |

|||||||||||||

| REMARK STELLA NEWS SITE is a free news site of FPD and PCB by Stella Corporation Inc.(This company does not release these FPD and PCB related products.) |

| Situation of benchmark test We are testing various treatments in respective lacations by using customer's sample substrate always. Situation of benchmark test is this page. |