STELLA NEWS SITE is managed by Stella Corporation Inc. |

Innovation Japan 2024 (August 22 - 23) |

|||||||

August 22 - 23th, Innovation Japan 2024 was held in Tokyo Big Site. New topics of electric device are closed up. As concerns perovskite solar cell, Sophia University proposed new perovskite compounds based on new concept.

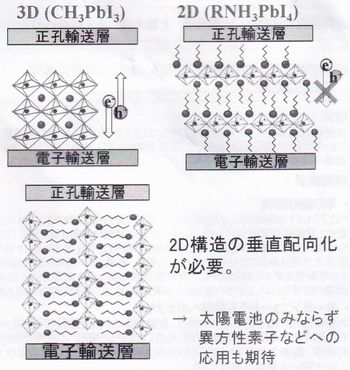

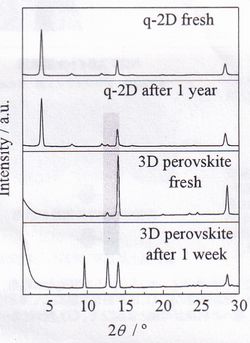

However, in 2D structure, vertical carrier movement is decreased because of hydrophobic group. For this reason, it's necessary to vertically orientate 2D compound. As its methods, molecule structure, balance control of hydrophobic and hydrophilic groups, coating method, kind of solvent and others are necessary to devise. For the present moment, IPCE (Incident photon-to-current efficiency) of 2D type Pb series perovskite device is approximate 10 %. In near future, the research group will develop Sn series perovskite device with high IPCE, is competed with Pb series device. Amorphous ITO film is crystallized by irradiation of DUV laser

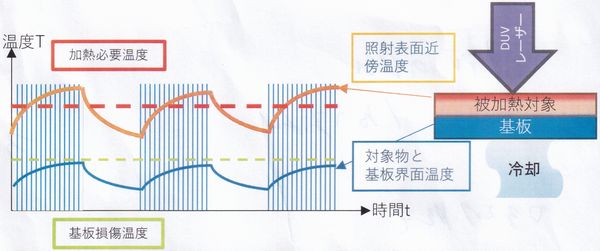

For example, amorphous ITO can be crystallized completely and easily by this method. And also, if deposited Cu film is irradiated by DUV laser, film resistance is decreased because of increase of Cu grain size. Furthermore, if two or three metals (solid) are put on plastic substrate, they are changed to alloy films by this method. Self-repairing and chemical recycle are realized by use of originally optical resin

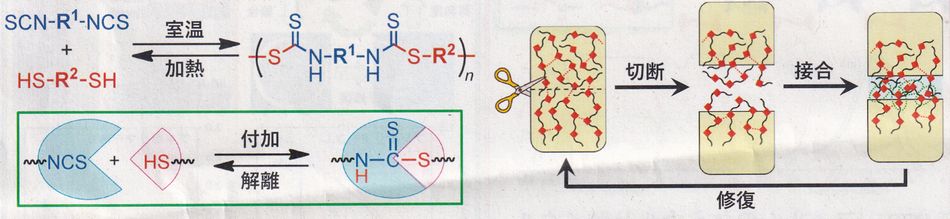

The research group has succeeded to develop polydithiourethane (PDTU). As figure 4, at room temperature, it's self-repaired by polyaddition. On the other hand, it can be recycled because of depolymerization by anneal at 150 üÄ. In short, self-repairing at light damage, chemical recycle at deep damage are realized. Picture 1 shows PDTU sheets. Its transmittance is 75 % and over. For this reason, it can be used as optical film and sheet, lens, and so on.

|

|||||||

| REMARK STELLA NEWS SITE is a free news site of FPD and PCB by Stella Corporation Inc.(This company does not release these FPD and PCB related products.) |

Novel system was released as manufacturing system of emulsion film mask. |