STELLA NEWS SITE is managed by Stella Corporation Inc. |

The Total Solution Exhibition for Electronic Equipment 2021 (October 27-29) |

|||||||||||||

October 27-29, The Total Solution Exhibition for Electronic Equipment 2021 was held in Tokyo Big Sight. Main topics in this exhibition are picked up. Dedicated blade edge was developed for flexible glass of NEGYamagata University exhibited OLED lighting devices using ultra-thin flexible glass "G-Leaf", which was developed by Nippon Electric Glass (NEG). In this device, all layers inclusive of electrodes and organic layers were deposited continuously by the Roll to Roll method. If G-Leaf is used as a substrate, flexible OLED with high mechanical strength and gas barrier property can be easily manufactured.

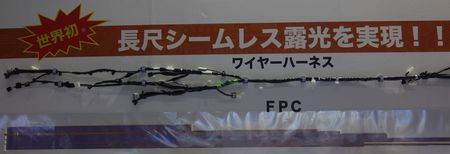

Its scribing speed is 100ço/sec. The company is releasing a dedicated cutting system "MUGP9010" and SOLID-D. By the way, MUGP9010 is a sheet type system, but Roll to Roll type system has been developed yet. As picture 1, a variant OLED was exhibited in the booth. The project group indicated that this technology was effective for not only simple cutting, but also variant fabrication. Roll-to-Roll type direct imaging system is practical use for long FPCs

As picture 2, the company exhibited wire harness and long FPC in the booth. Firstly, the company proposes this system in the automobile system for long FPCs, which is replacer of wire harness. Upper ITO electrode can be used to organic device by relaxation of stress in deposition process As concerns manufacturing process, National Institute of Advanced Industrial Science and Technology (AIST) appealed degradation of characteristics of organic devices could be avoided by relaxation of stress in ITO electrode deposition process.

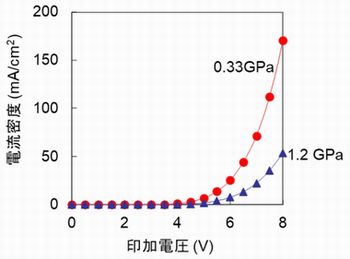

Therefore, a transparent OLED with upper ITO transparent electrode was pilot-produced. Its device was composed of ITO anode/NPB/Alq3/LiF:MgAg/ITO cathode. In proportion as reduce of stress in ITO film, as figure 1, J-V curves of device was enhanced. Epoxy film becomes to be a candidate of newly transparent plastic film As regards material, Mitsubishi Chemical exhibited an epoxy film as a new transparent plastic film. Various inks, pastes, and liquids can be directly coated and printed on this film without buffer layer because of high adhesiveness, which is essential property of epoxy resin. Furthermore, thermal resistance is superior because of Tg free. Transmittance and coefficient of thermal expansion are approximate 85% and 54 - 71ppm respectively.

Reference 1)Suemori, et.al.üFControlling the internal stress of ITO layer for improving the performance of transparent organic light emitting diode , The 82th JSAP Autumn Meeting, 2021, 11-286 (2021.9) |

|||||||||||||

| REMARK STELLA NEWS SITE is a free news site of FPD and PCB by Stella Corporation Inc.(This company does not release these FPD and PCB related products.) |

|