STELLA NEWS SITE is managed by Stella Corporation Inc. |

ITE Technical Report-Information Display- (August 2, 2019) |

||||

August 2, 2019, gITE Technical Report-Information Display-h was held in

Tokyo. In this here, two oral presentations are picked up.

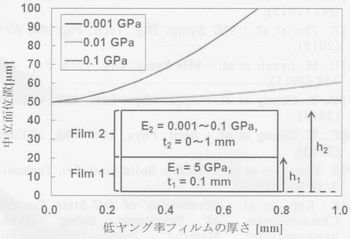

Concretely, a cover film with very low Young's modules was used as its key material. Its functions are the following:@Robustness is enhanced by thickening of device, AShock resistance is enhanced by relaxation of mechanical damage, BNeutral plane is not almost changed. Neutral plane means to be zero stress state. If device is bended, stress in this plane is not generated, as a result, robustness is greatly enhanced. For this reason, display device would like to be placed near neutral plane.

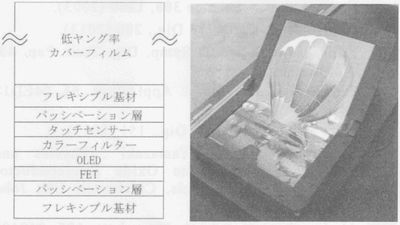

Figure 2 shows cross-section structure and picture of pilot-produced 8.56 inch. flexible OLED. In this device, robustness and bendability were ensured at the same time by making use of a cover film with low Young's module. And also, in spite of RGB independent color OEL method, micro color filter (RGB) and black matrix were adopted on the front substrate due to without circle polarizer. By the way, this panel was bended after 100 thousands at R = 3 o, display property was almost degraded. A novel reactive monomer is doped into LC due to alignment film-free

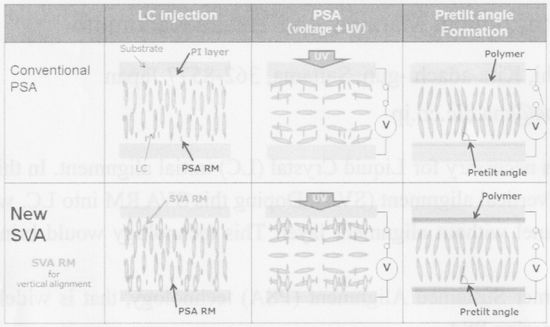

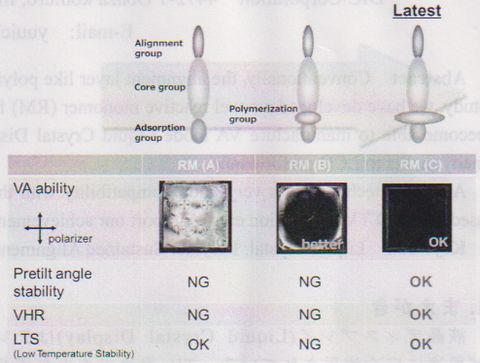

Figure 3 shows comparison of the conventional polymer sustained alignment (PSA) and this SVA. In the latter, SVA-RM and PSA-RM are doped into liquid crystal host material, and then, it is filled into LC cell, finally, pretilt angle is obtained by polymerization of RM using irradiation of UV light.

And also, remained RM after UV irradiation was almost zero, which was same as that of PSA. In short, the conventional UV irradiation process can be adopted, too. Furthermore, if low pressure UV light (peak wavelengthF185 nm and 254 nm) was irradiated to ITO electrode, VA alignment property was drastically improved for mere 10 seconds. This process was confirmed to be effective for mass production. Reference 1)Sugisawa, et.al.FA Flexible OLED Display with Robustness and Bendability, ITE Technical Report-Information Display-, pp.13-16 (2019.8) 2)Inoue, et.al.FA Novel Reactive Monomer for Self Vertical Alignment, ITE Technical Report-Information Display-, pp.9-12 (2019.8) |

| REMARK STELLA NEWS SITE is a free news site of FPD and PCB by Stella Corporation Inc.(This company does not release these FPD and PCB related products.) |

|