OPEN HOUSE 2024 Full-color Mini-LED and Micro-LED using liquid metal electrode

were exhibited

May 30 - June 3rd, OPEN HOUSE 2024 was held in NHK Science & Technology

Research Laboratories. As concerns display, full-color Mini-LED and Micro-LED

using liquid metal electrode were exhibited for the first time, instead

of mono-color LEDs, was exhibited at last year.

NHK Science & Technology Research Laboratories exhibited LED disformable displays at last year. It's fully flexible LED display using originally developed stretchable electrode. In this time, outline of stretchable electrode was announced in part.

Concretely, liquid metal electrode was used due to synchronized deformation at stretching time. As name, it functions as wiring even as liquid. In this time, Ga series material was used. Melting point of Ga is very low same as 29.8 , but some dopant was doped, as a result, that of Ga series material was decreased to a dozen . For this reason, liquid state keeps at room temperature. Filler and solvent are not contained in this material. As a result, after adhesion on the substrate as electrode, this material functions as liquid. Therefore, not only electrode is not broken, but also, its specific resistance is not changed in stretching.

Pic.3 Full-color Mini-LED with dome shape |

Pic.2 Application samples of full-color Mini-LED using stretchable electrode |

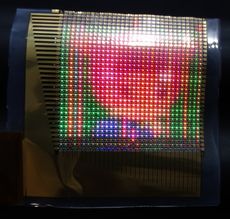

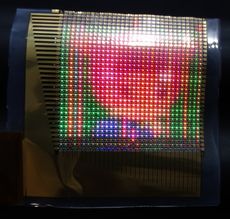

Pic.1 Full-color Mini-LED using stretchable electrode |

As regards forming method of this electrode, a metal mask is put on the substrate, and then, liquid metal is filled and printed into opening area of metal mask. After unsetting metal mask, a silicon resin is coated as encapsulation film due to fixing electrode. After printing, it's annealed by a secret method. For the present moment, printing resolution and pitch is approximate 300 Κm and 1.5 mm respectively. However, its specific resistance is higher at single digit or double digits compared to that of general wiring such as Al, Cu and so on.

As concerns manufacturing process of LED display, firstly stretchable electrode is printed on original glass substrate, and then, commercial micro-LED chips are mounted on the electrode. Finally, original substrate is stuck a acrylic rubber sheet, and then, released from original substrate. Stretchable ratio was increased from 40 % (last year) to 50 %.

In this time, full-color Mini-LED and full-color Micro-LED were exhibited by arraying RGB-LED chips. The former is 100 ~ 100 mm size, and composed of 20 ~ 20 LED chips (2 ~ 3 mm) at 5 mm pitch. As picture 2, it's effective for wearable applications because of disformable property.

Pic.5 Green color Micro-LED with dome shape |

Pic.4 Full-color Micro-LED using stretchable electrode |

The later is 64 ~ 64 mm size, and composed of 32 ~ 32 LED chips (20 ~ 30 Κm) at 2 mm pitch. It's useful for mobile system and specific shape applications because of higher resolution compared to that of Mini-LED. For example, it's possible to produce dome shape display easily. As picture 3, Mini-LED with convex dome shape and Micro-LED with concave dome shape were disclosed. They were shaped by blowing or introducing air. By the way, green mono-color Micro-LED (picture 5) with concave dome shape is highest resolution device same as 1.5 mm pitch in the exhibited samples.

Any way, their completion ratio were high such as high brightness because of use of commercial LED chips. As regards road map, prototype display will be pilot-produced at 2025, and then, practical display will be developed at 2030.

Transparent organic film solar cell was disclosed for window glass and etc.

Pic.7 Driven glass type radio by transparent organic film solar cell |

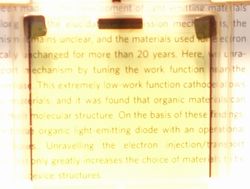

Pic.6 Transparent organic film solar cell |

On the other hand, transparent organic film solar cell was exhibited. It's a original device using a specific material for OLED. However, composition of this material was not disclosed. Device structure is p-n junction type small molecular device, and their layers were deposited by general evaporation method. In short, it's classic and beginning device, and its incident photon-to-current efficiency (IPCE) is very low same as approximate 1 %.

However, its transmittance is very high same as 75 % because of effective absorption of UV light. As picture 6, viewer can see background by intermediary of this transparent organic film solar cell. Furthermore, commercial E-paper and glass type radio (picture 7) were driven by this solar cell in the booth. It's shown that it was effective for transparent applications such as window glass. |