STELLA NEWS SITE is managed by Stella Corporation Inc. |

Kumamoto University New Technology Presentation Meetings (October 30) |

|||

October 30, 2018, gKumamoto University New Technology Presentation Meetingsh was held in JST. In this here, an oral presentation by Dr. Nakanishi is picked up.

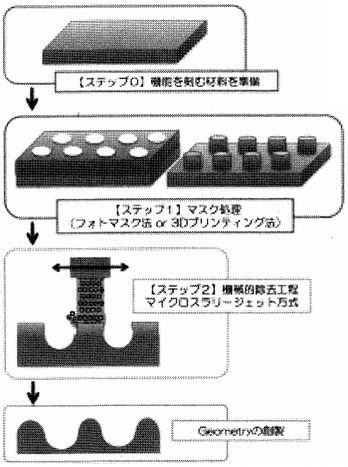

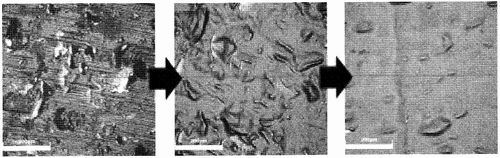

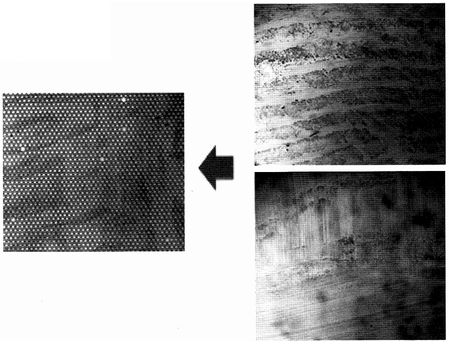

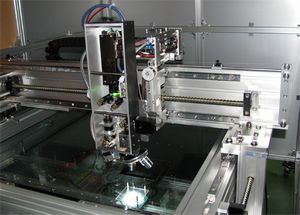

As figure 1, first of all, a masking pattern is directly formed on light curing resin mask by the conventional processes, such as the 3D printing method, the photo etching method. The next, modification surface is mechanically patterned by the slurry jet method using slurry with Al2O3 abrasive compound. In this time, mask and base substrate are dry-etched at the same time. As a result, if mask is eliminated, a desired asperity pattern is formed on the base substrate. It's not chemical modification, so that, it's unnecessary to use medicinal solutions, such as photoresist, etchant, and its remove process. In short, this process is combination of the conventional methods. Its main application is bio-inspired surface. In short, new functions is gained by fine surface structure, which is likely to leaf of lotus, eye of moth, and so on. For example, if above slurry treatment is done without pattern modification, contact angle of water changes from 20 to 60approximately. Shortly, hydrophobic effect is realized, as a result, fingerprint and pollution become to be difficult to adhere to the surface. Picture 1 shows surface treatment of the ceramic substrate. After this treatment, surface roughness was decreased, as a result, mechanical strength is increased. And also, if a mold for resin is treated by this process, residual dross of resin can be minimized due to enhancement of antifouling property. In short, fabrication precision and lifetime will be expected to be enhanced. Picture 2 shows modified glass with dot pattern, is likely to leaf of lotus. Reference 1)NakanishiFSurface patterning technology to be possible to correspond to various materials, large substrates, and 3D curved plates, Kumamoto University New Technology Presentation Meetings!, pp.3-6 (2018.10) ¦This title is translated arbitrarily by Stella News Site because of without English edition of presentation material.

|

| REMARK STELLA NEWS SITE is a free news site of FPD and PCB by Stella Corporation Inc.(This company does not release these FPD and PCB related products.) |

|